Mold Making for Wax Casting

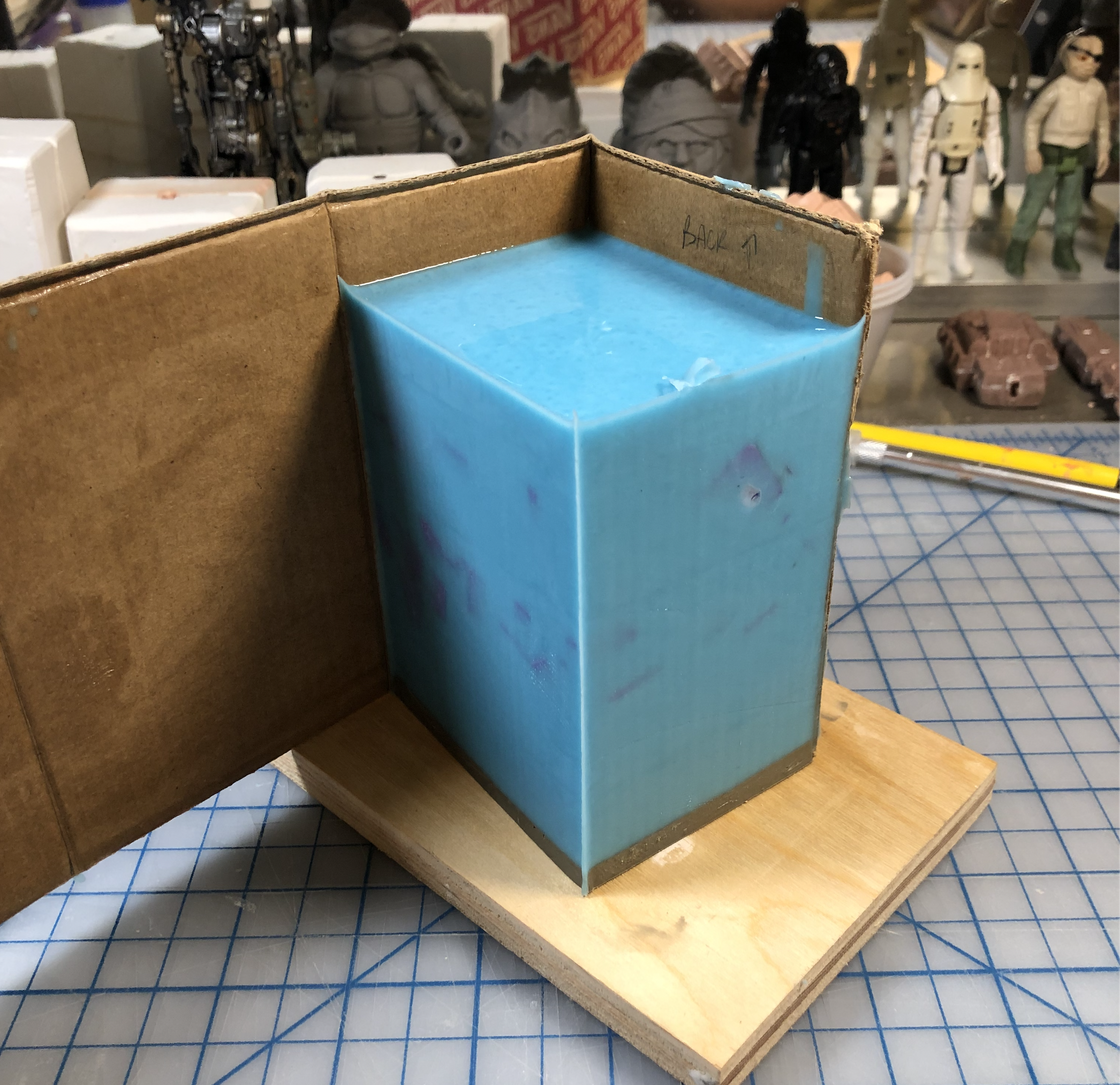

The type of mold you make impacts how long your mold will last. While silicone products like Smooth-On Oomoo or even alginate will work, the mold will deteriorate faster than other products that are designed for high temperatures and small pieces of the mold may end up tearing out after each pull, resulting in only a few high quality castings. However, that may be enough for your particular project though - but you’ll have to make that determination yourself.

Smooth-on’s high temperature silicone works well for this application but other brands will work as well, just read the data sheet and look for the high temperature tolerant silicones.

Something to keep in mind when you’re making your molds - just like resin, it has a tendency to shrink down into the mold and leave a sharp edge around the base of the pour, wax will also shrink a bit, and you may be left with a low spot in the middle, so plan accordingly and add another 1/8’ buffer to the base of your model before making your mold. You can then remove the excess much easier after pouring instead of trying to add more to it to fill in the shrinkage, which makes life easier and life is hard enough, right? Right.

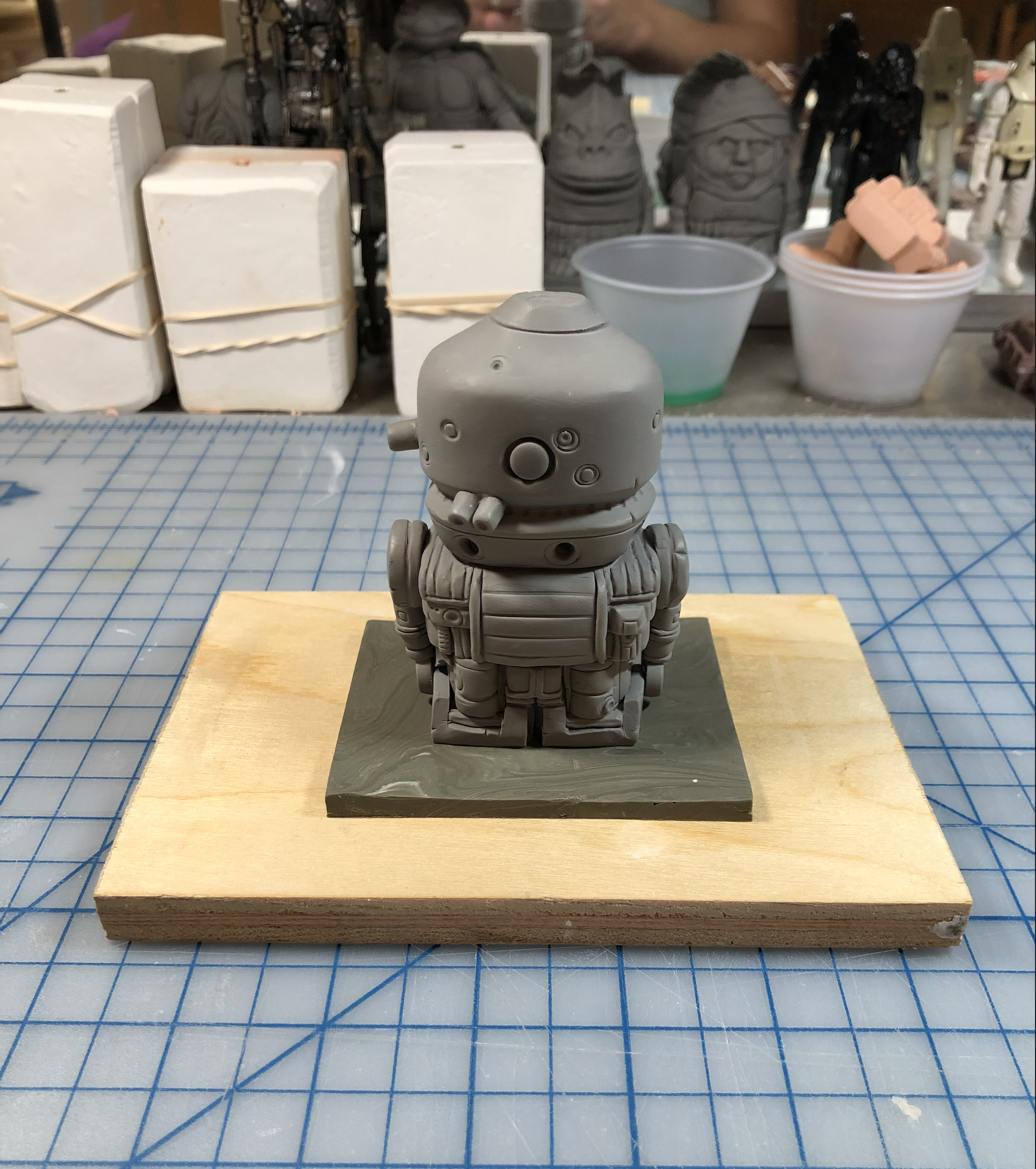

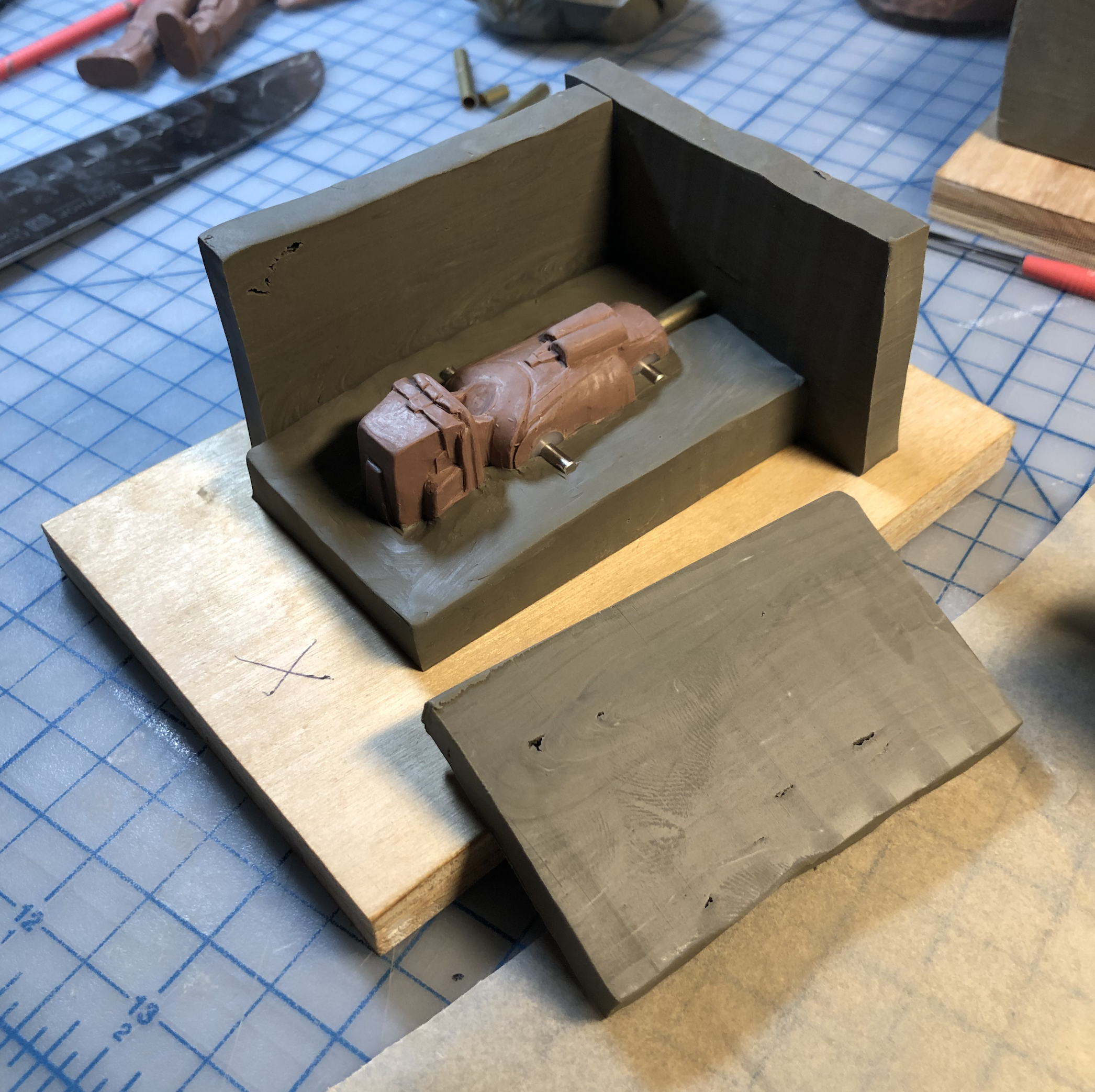

Getting started with clay roughs or existing models

Starting your sculpt with a ‘clay rough’ is an excellent way to get your gesture and main forms refined before going to wax to refine the detail. Clay gives you the freedom to quickly modify the sculpt as it takes shape.

Once you’ve refined those key aspects of the sculpt, it’s time to make a mold of it to use for wax casting.

Molding Mediums

The goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long.

That said, there are a few good options that have unique advantages depending on your goals:

Alginate molds

Alginate is a great mold making material. This is the stuff your orthodontist uses to take molds of your teeth. It is water-based, non toxic, and takes a very accurate impression. However, it tears easily and does not hold up to use over time.

Advantages – Inexpensive and readily available. It can be chopped up and reused as long as it stays moist.

Disadvantages – Good for only a handful of casts. It can dry out and warp the mold cavity.

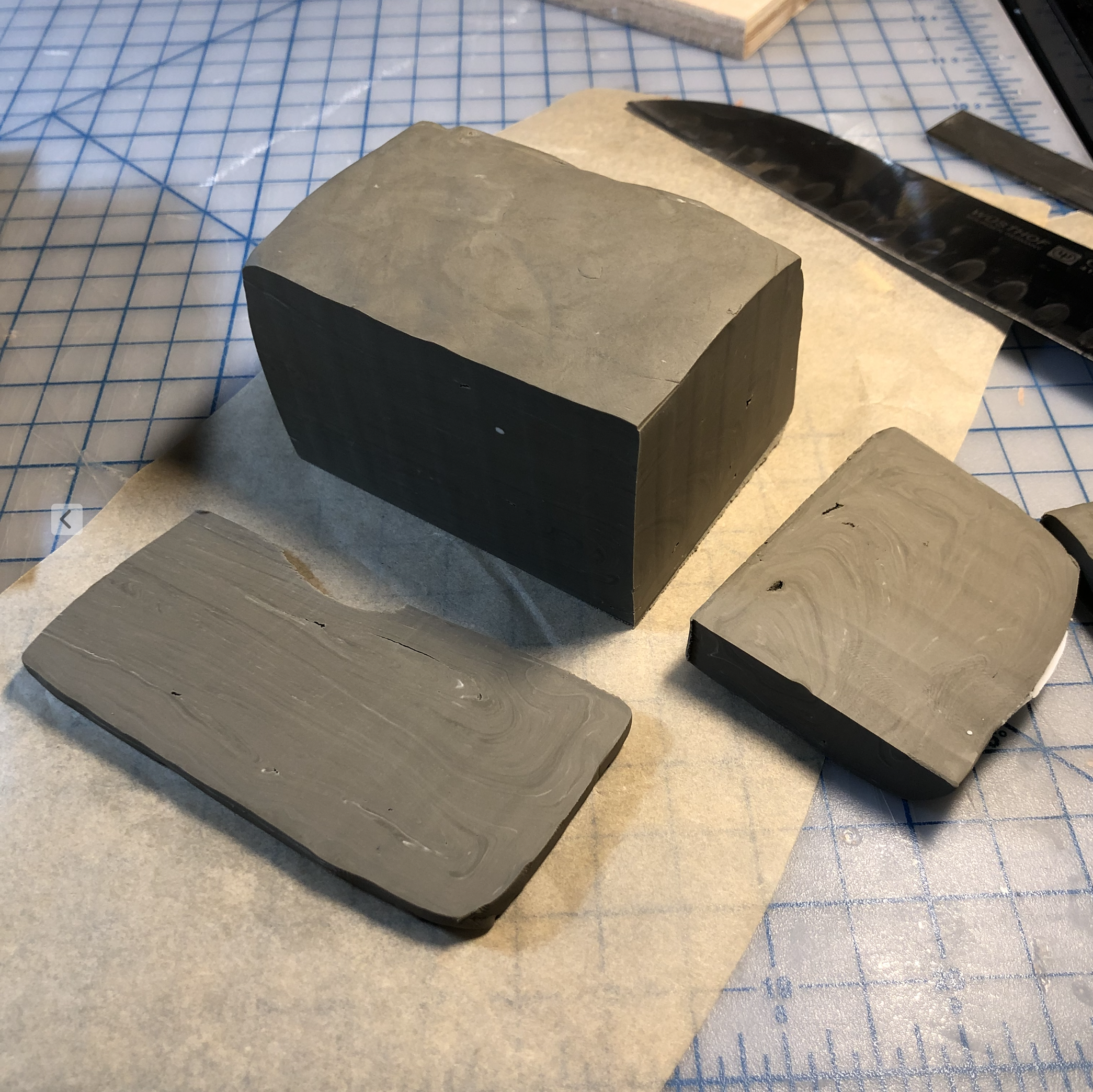

Plaster molds

Unlike alginate and silicone, plaster molds are rigid. This requires that molded pieces are free of undercuts that would making removing castings from the mold impossible without breaking the mold. Beside that, it’s a cheap alternative to silicone and will last longer than alginate.

When casting wax in plaster molds, it’s important to keep the plaster damp, allowing castings to be easily removed.

Advantages – Inexpensive and readily available. Lasts longer than alginate.

Disadvantages – Rigid material this is inflexible and can break or chip. Clay and wax can stick to plaster, so be sure to use a light mold release.

Silicone molds

Silicone is an excellent mold material. Its flexibility allows you to mold and cast hard items and picks up very minute detail.

Silicone would be the material of choice if you want to a create a blank casting that you plan to modify again over time.

Advantages – Silicone is flexible and can last a long time.

Disadvantages – Silicone is expensive compared to alginate and silicone.

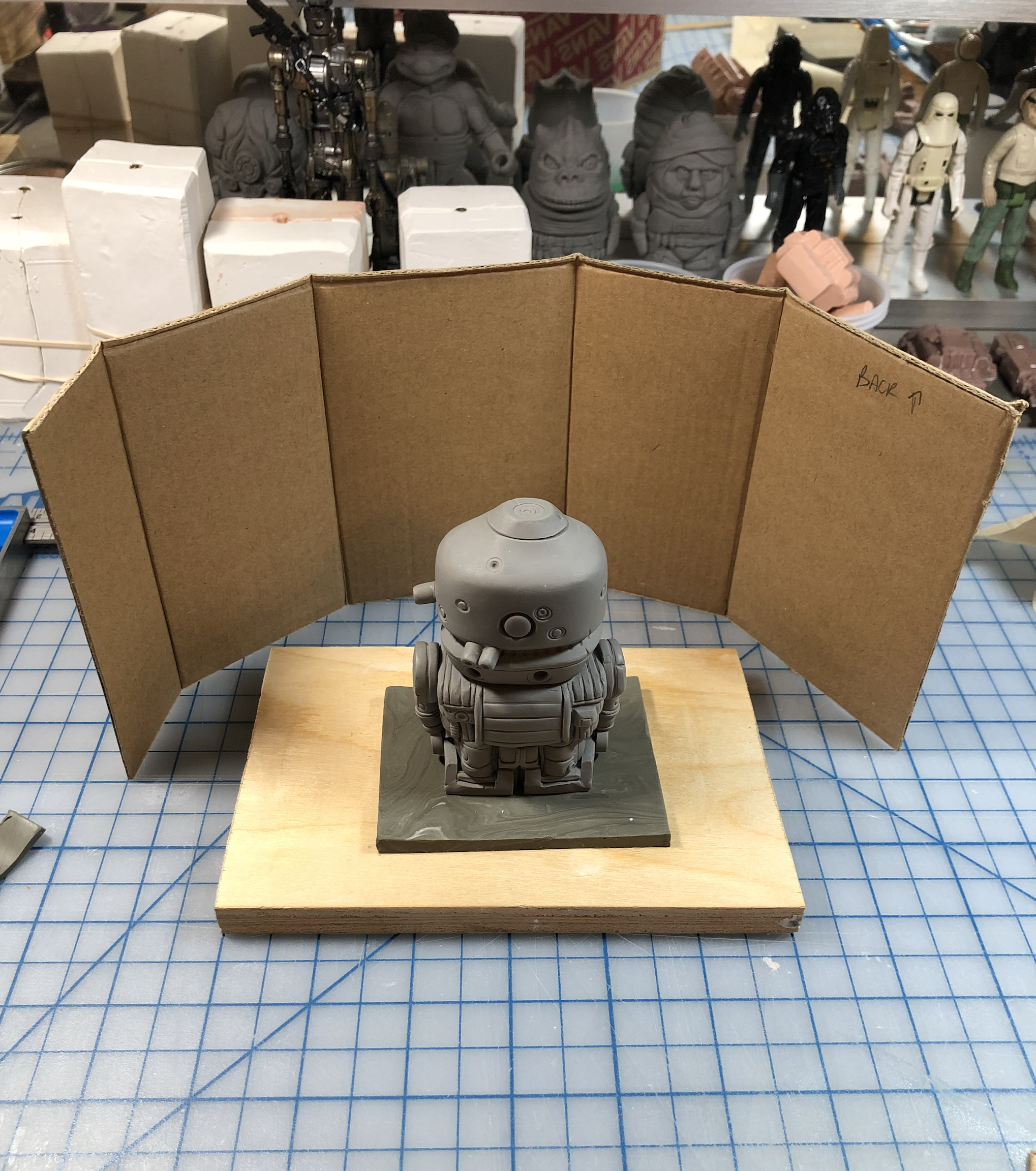

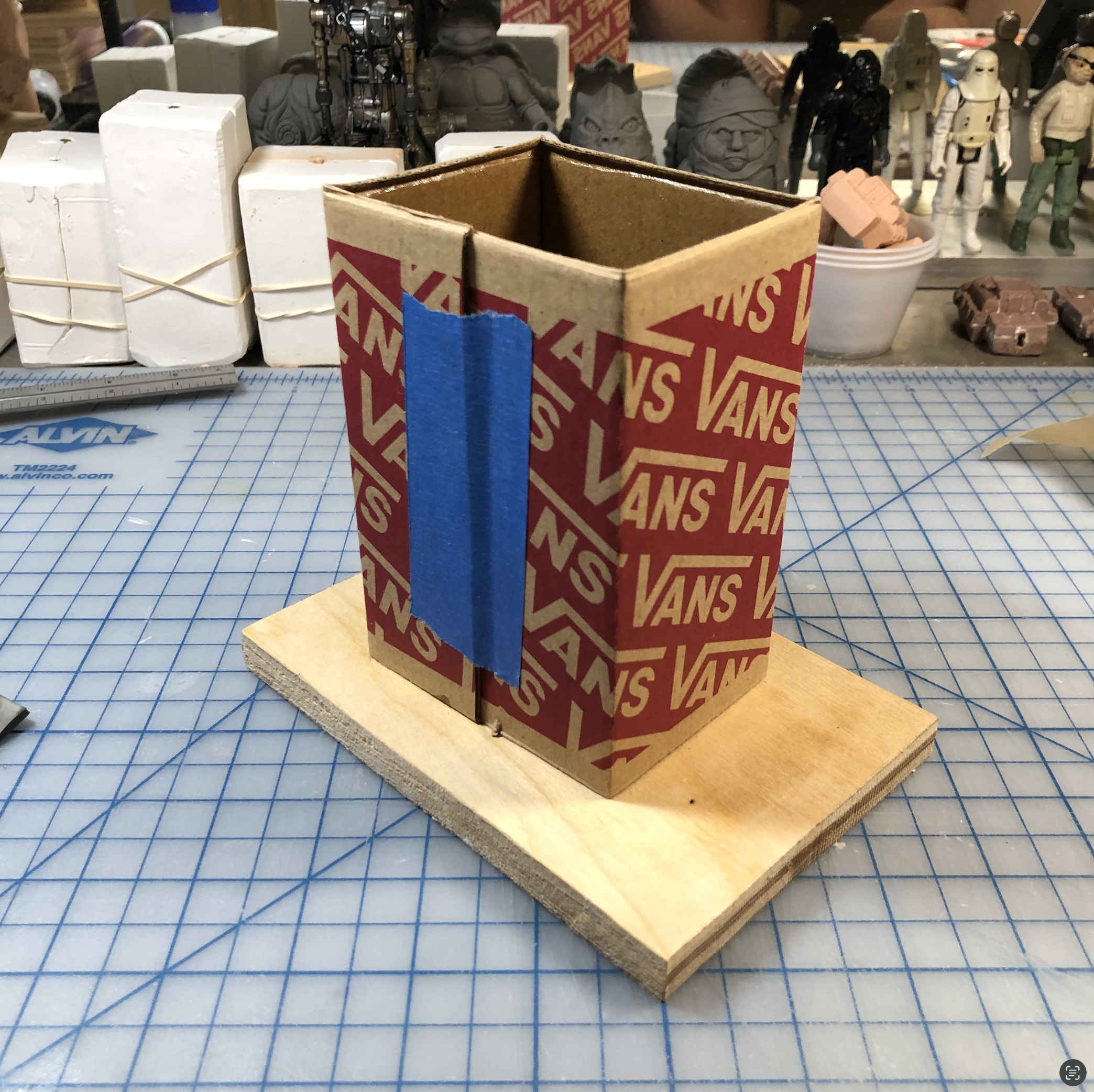

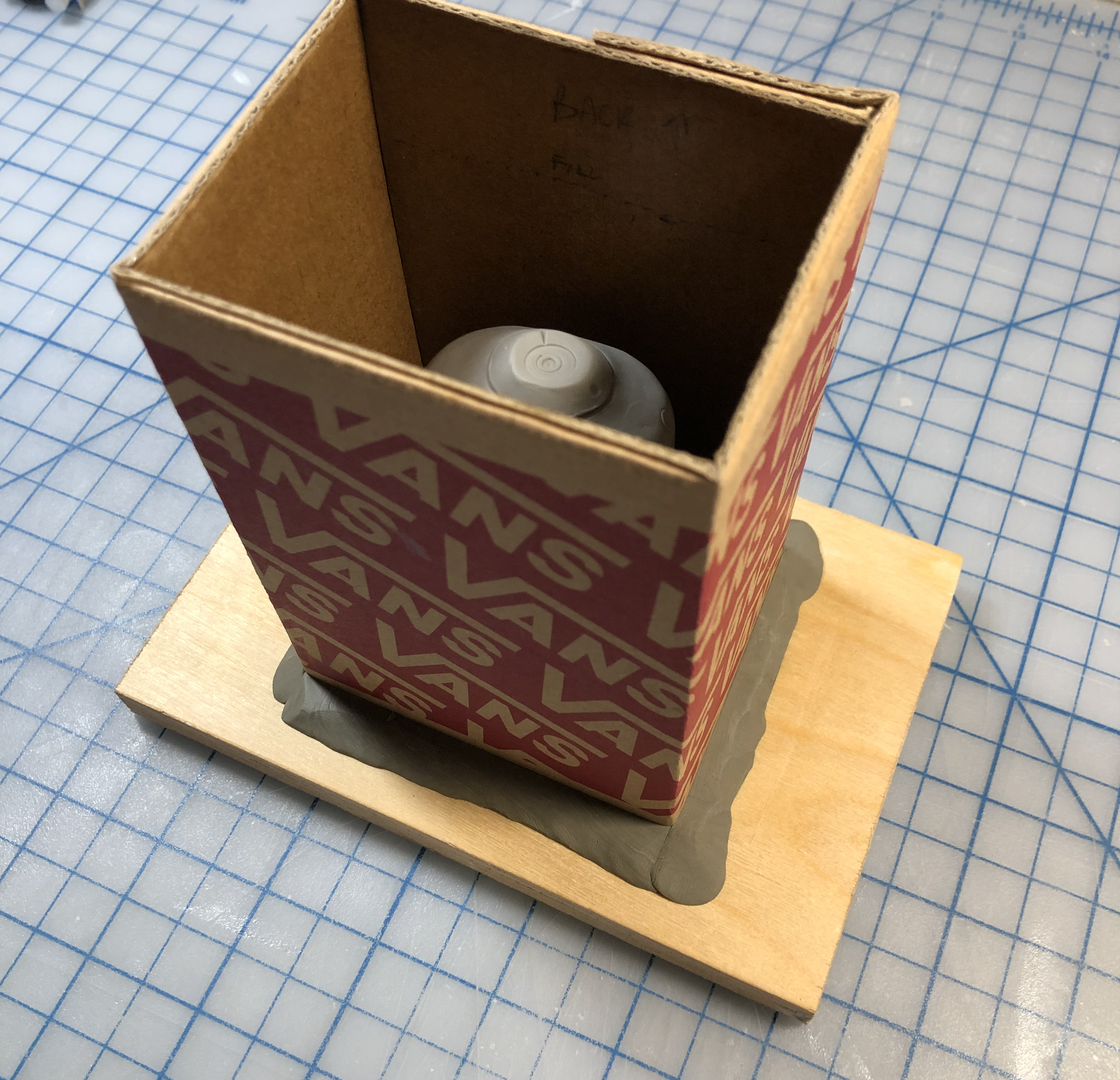

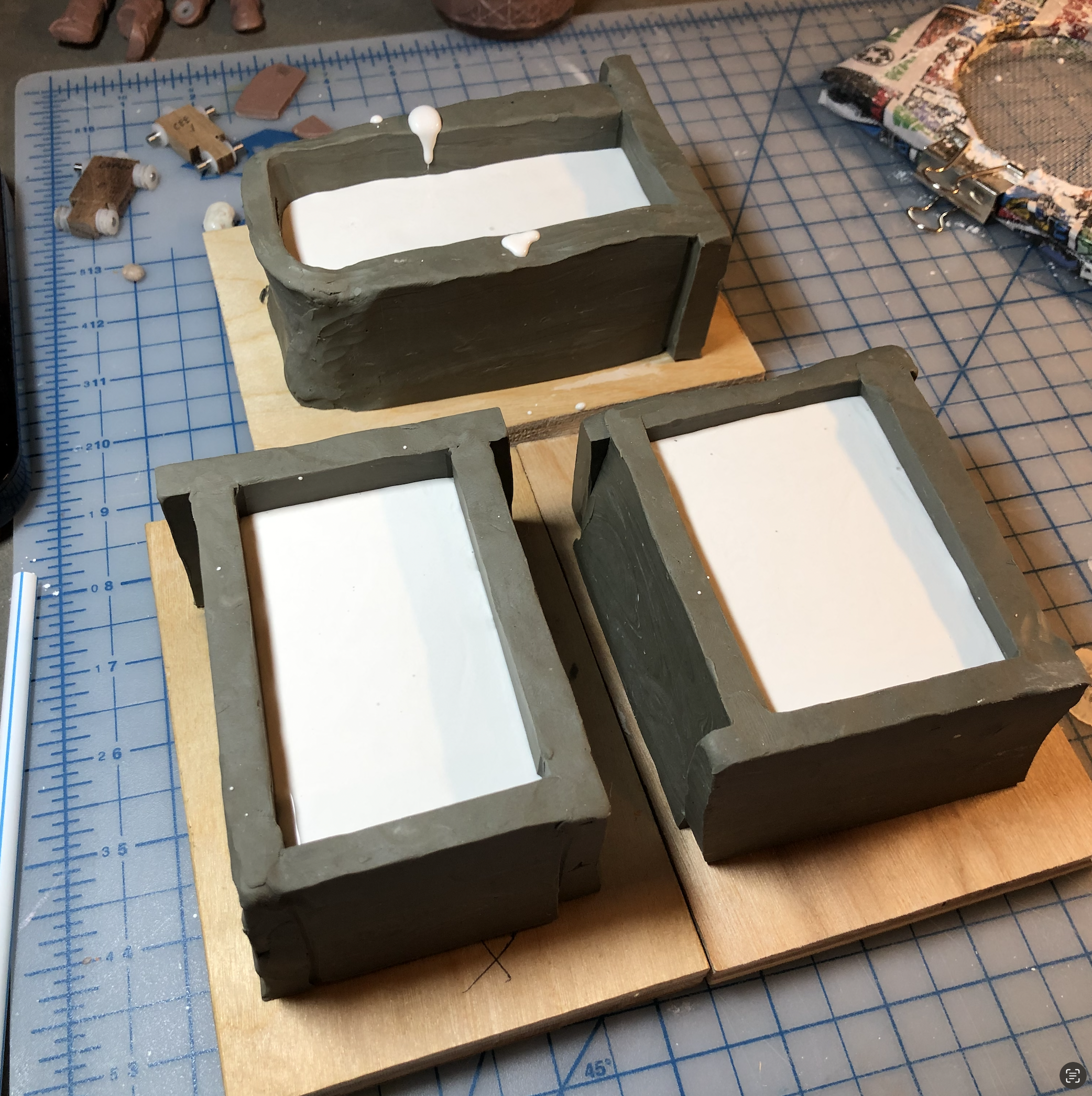

Constructing a mold box

There are numerous ways to make mold, however these are two we’ve used among others.

The basic construction of a mold is wall that surrounds your model, fixed to a solid base. All joints are sealed to ensure the mold material won’t leak out.